Plastic part inspection

CMM and Projector to measure the parts according to the 3D and 2D drawing

Standard parts

Quick check on standard parts, such as type, brand and main diameters to ensure standard part within required tolerance.

All components inspection

Before delivery of molds, All screws, components will be well cleaned and mold surface will be well check before assembly

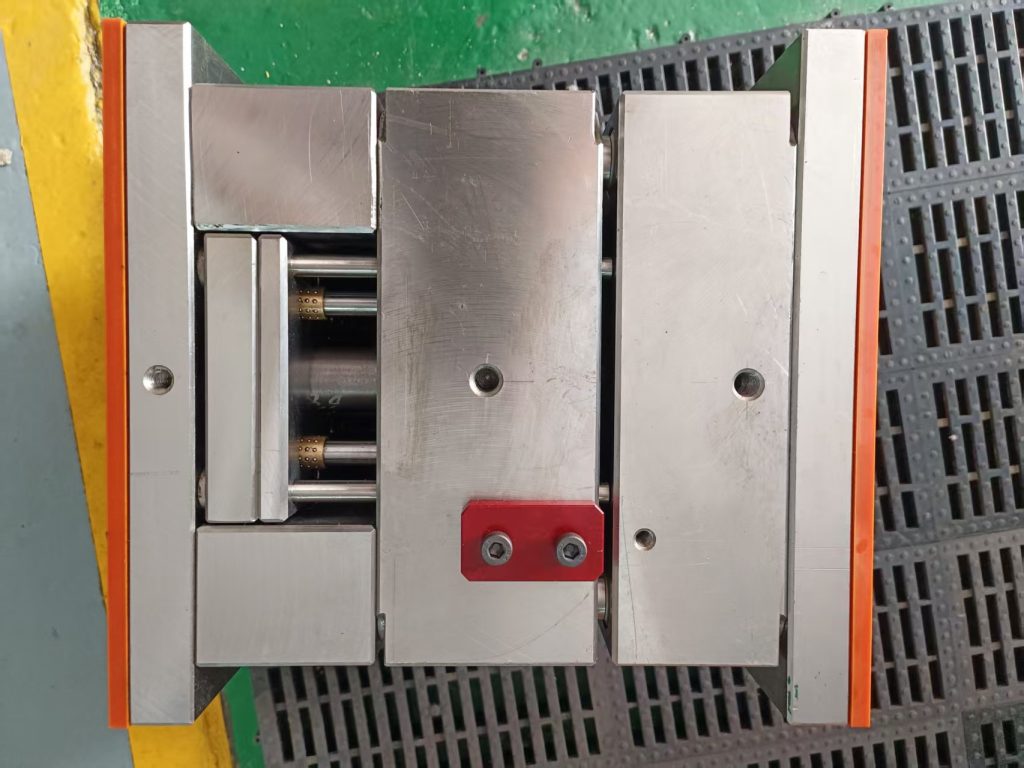

Mold components inspection

Main core insert, cavity insert and sliders will be inspection will be measured before tool assembly to eliminate potential mistakes

Moldbase Inspection

Plate thickness and flatness, core and cavity pocket tolerance. good moldbase performance is a important role during mass production

Packaging inspection

Molds will be fully protected with vacuum bags and steel ropes on wooden boxes